How to Detect and Stop Galvanic Corrosion in Pipes

- What is Galvanic Corrosion?

- Causes of Galvanic Corrosion in Pipes

- How to Detect Galvanic Corrosion in Pipes

- How to Stop Galvanic Corrosion in Pipes

- Real-Life Examples of Galvanic Corrosion

Galvanic corrosion is a significant concern when it comes to plumbing systems, especially in areas where different metals are used in close proximity. If left untreated, this form of corrosion can lead to leaks, damage, and costly repairs. In this article, we will explore what galvanic corrosion is, how to detect it in your pipes, and the best methods to stop it from spreading.

Missouri Trenchless Pipe- Lining LLC

OwensvilleGasconade CountyMissouri

1844 US-50, Owensville, MO 65066, USA

1. What is Galvanic Corrosion?

Galvanic corrosion occurs when two different metals are in electrical contact in the presence of an electrolyte, such as water. This interaction causes one metal to corrode more quickly than the other. Typically, the more reactive metal (the anode) corrodes, while the less reactive metal (the cathode) is protected.

In plumbing, galvanic corrosion often happens when dissimilar metals, such as copper and steel, are connected. Over time, the electrochemical reaction can cause the anode metal to deteriorate, leading to leaks, weakening of the pipe structure, and even pipe failure. Understanding how galvanic corrosion occurs is key to preventing it in your home’s plumbing system.

2. Causes of Galvanic Corrosion in Pipes

Galvanic corrosion in pipes is primarily caused by the following factors:

- Dissimilar Metals: When different metals, such as copper and steel, come into direct contact with each other, galvanic corrosion can occur. This often happens when fittings or pipes of different materials are used in the same system.

- Water Quality: The type of water in your pipes plays a significant role in galvanic corrosion. Water that is highly acidic or has high levels of dissolved salts and minerals can accelerate the electrochemical process that leads to corrosion.

- Electrical Grounding: Electrical currents that pass through plumbing systems can exacerbate galvanic corrosion. This can happen if there is improper grounding or if plumbing is directly connected to electrical systems.

- Improper Installation: When plumbing systems are not properly installed, it can lead to the mixing of metals or allow moisture to cause electrochemical reactions. A poorly sealed connection between different materials can increase the risk of galvanic corrosion.

3. How to Detect Galvanic Corrosion in Pipes

Detecting galvanic corrosion early on can help prevent serious damage to your plumbing system. Here are a few signs to look out for:

- Discoloration or Pitting: If you notice discoloration or pitting around pipe joints, it may indicate the start of galvanic corrosion. The area around the corrosion might appear darker or have small holes or indentations.

- Leaking Pipes: One of the most obvious signs of corrosion is water leakage. If you notice water stains on walls, ceilings, or floors near pipe connections, it may be a result of a corroded pipe.

- Unusual Water Pressure: Galvanic corrosion can lead to blockages in your pipes, which may cause low water pressure. If your water pressure has dropped without explanation, it could be due to corroded pipes narrowing the passageway.

- Visible Rust or Debris in Water: If you see rust-colored water or debris coming out of your faucets, it may be due to corroded metal pipes breaking down and releasing particles into the water supply.

Regular inspections and maintenance can help you spot these issues early before they lead to more significant problems like pipe failure or flooding.

4. How to Stop Galvanic Corrosion in Pipes

Once galvanic corrosion has started, it's essential to take action immediately to stop it from spreading. Here are several ways to prevent and stop galvanic corrosion in your plumbing system:

- Isolate Dissimilar Metals: One of the most effective ways to prevent galvanic corrosion is by isolating different metals from each other. Use dielectric unions or rubber gaskets to separate metals like copper and steel. This will prevent direct electrical contact between the materials.

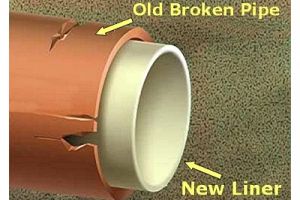

- Replace Corroded Pipes: If you notice significant corrosion on your pipes, replacing the affected sections may be necessary. Upgrading to corrosion-resistant materials like PEX or CPVC can prevent further issues.

- Regular Maintenance: Periodically check your plumbing system for any signs of corrosion or wear. Pay particular attention to pipe joints and connections where different metals may come into contact.

- Use Protective Coatings: Applying protective coatings or pipe wraps can help reduce the risk of corrosion. Some coatings are designed to insulate the pipes and prevent moisture from creating an environment conducive to corrosion.

- Proper Grounding: Ensure that your plumbing system is properly grounded and that electrical systems are not improperly connected to the plumbing. This reduces the chance of electrical currents accelerating corrosion.

5. Real-Life Examples of Galvanic Corrosion

Consider the case of John and his family, who experienced significant water damage due to galvanic corrosion in their home. Their plumbing system included both copper and steel pipes, and over time, corrosion developed at the joints. The corrosion went unnoticed until they began experiencing water leaks and low water pressure in their kitchen and bathrooms. After having the pipes inspected, they learned that the dissimilar metals were causing galvanic corrosion, leading to pipe failure.

In another instance, Sarah and Mark had their old plumbing system replaced with a more modern setup. The new pipes used PEX and CPVC materials, which are more resistant to corrosion and compatible with their existing systems. By isolating the metals and replacing older sections of their plumbing, they effectively stopped the spread of galvanic corrosion.

These real-life examples show how important it is to detect and prevent galvanic corrosion early. With the right precautions and timely action, you can protect your home’s plumbing and avoid costly repairs.

If you're looking for expert advice or plumbing supplies to help prevent galvanic corrosion in your home, visit Plumbers Supply Hub. We offer a wide range of products designed to improve your plumbing system’s durability and efficiency, from corrosion-resistant materials to protective coatings.

Jayce Abel Plumbing, LLC4.0 (9 reviews)

Jayce Abel Plumbing, LLC4.0 (9 reviews) Roto-Rooter Plumbing & Water Cleanup4.0 (774 reviews)

Roto-Rooter Plumbing & Water Cleanup4.0 (774 reviews) Gateway Rooter & Plumbing5.0 (5 reviews)

Gateway Rooter & Plumbing5.0 (5 reviews) Affordable Plumbing & Drain Cleaning of Columbia5.0 (1 reviews)

Affordable Plumbing & Drain Cleaning of Columbia5.0 (1 reviews) Miller Plumbing4.0 (24 reviews)

Miller Plumbing4.0 (24 reviews) E.C. plumbing4.0 (18 reviews)

E.C. plumbing4.0 (18 reviews) How to Clean Sediment Build-Up in Household Pipes: Effective Solutions for Clear Water Flow

How to Clean Sediment Build-Up in Household Pipes: Effective Solutions for Clear Water Flow How to Install a Bidet Attachment Safely | Expert Plumbing Tips

How to Install a Bidet Attachment Safely | Expert Plumbing Tips How to Replace a Galvanized Pipe in Your Home

How to Replace a Galvanized Pipe in Your Home How to Repair a Sink That Drains Faster Than Faucet: Fixing Plumbing Issues Efficiently

How to Repair a Sink That Drains Faster Than Faucet: Fixing Plumbing Issues Efficiently How to Test an Expansion Tank on Your Water Heater

How to Test an Expansion Tank on Your Water Heater The Risks of Installing Incorrectly Sized Pipes

The Risks of Installing Incorrectly Sized Pipes