- 1. Why Backflow Preventer Testing is Essential

- 2. Steps to Test Your Backflow Preventer

- 3. Tools Required for Testing Backflow Preventers

- 4. Common Issues Found During Backflow Preventer Testing

- 5. When to Call a Professional for Backflow Testing

- 6. Conclusion: Ensuring Your Backflow Preventer Works Efficiently

1. Why Backflow Preventer Testing is Essential

Backflow preventers are critical devices that protect your water supply from contamination by preventing water from flowing backward into the system. Over time, these devices can become less effective due to wear and tear, debris, or improper installation. That’s why annual testing is necessary to ensure they’re functioning properly and safeguarding your drinking water.

Testing your backflow preventer annually not only ensures compliance with local regulations but also helps prevent potentially costly plumbing issues. Without regular testing, you risk the possibility of contaminated water entering your home or business, which can have serious health consequences. Testing allows you to catch issues early and avoid potential contamination risks.

C L O'Brien & Co Plumbing & Heating

Peoria HeightsPeoria CountyIllinois

728 E Cox Ave, Peoria Heights, IL 61616, USA

2. Steps to Test Your Backflow Preventer

Testing a backflow preventer requires following a systematic process to ensure the device is functioning correctly. Here’s a breakdown of the steps involved:

Rodney Terry Plumbing

LouisvilleJefferson CountyKentucky

3266 Ruckriegel Pkwy, Louisville, KY 40299, USA

2.1 Turn Off the Water Supply

Before you begin testing, make sure to turn off the water supply to the backflow preventer. This prevents water from flowing through the device during the testing process, allowing you to assess whether the backflow preventer can effectively stop any reverse flow.

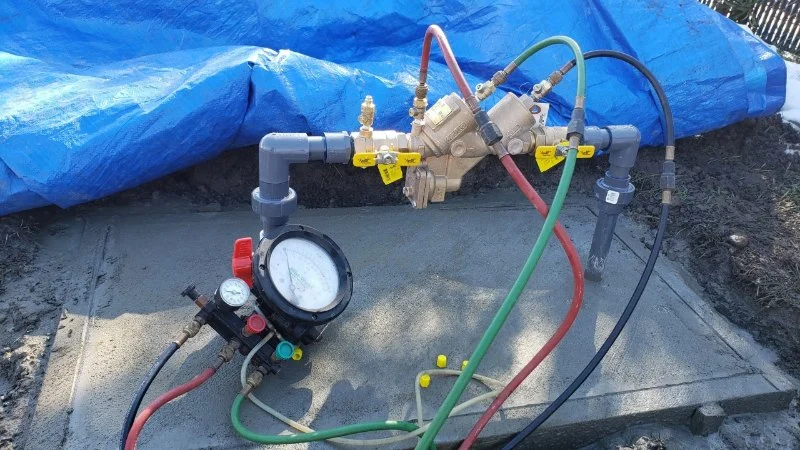

2.2 Attach the Test Kit

To test the backflow preventer, you’ll need to use a backflow test kit, which includes several hoses, gauges, and adapters. Attach the appropriate gauges to the test cocks on the preventer. The test kit will measure the pressure within the backflow preventer and check for any irregularities that may indicate a malfunction.

2.3 Perform the Test

With the test kit connected, you will need to follow the test procedure outlined for your specific type of backflow preventer. Most tests involve checking the shutoff valve, the check valve, and the relief valve to ensure that they’re all operating properly. If the test indicates that any part of the backflow preventer is not functioning correctly, further inspection or maintenance may be required.

2.4 Reopen the Water Supply

Once the test is complete, and if everything passes, you can safely reopen the water supply. Afterward, check the system to ensure there are no leaks or pressure irregularities. If the backflow preventer fails the test, it’s important to address the issue immediately to ensure the continued protection of your water system.

3. Tools Required for Testing Backflow Preventers

Testing backflow preventers requires a few specialized tools to ensure accuracy and safety. Here are the essential tools you'll need:

3.1 Backflow Test Kit

The most important tool for testing a backflow preventer is a backflow test kit, which includes hoses, gauges, and adapters specifically designed for this purpose. These kits allow you to measure the pressure within the device and assess its functionality.

3.2 Pressure Gauges

Pressure gauges are used to measure the pressure in different parts of the backflow preventer. These gauges help determine if the device is working within the necessary pressure range to prevent backflow. They are an integral part of the backflow test kit.

3.3 Wrenches and Tools for Valve Adjustment

In some cases, you may need to adjust or tighten certain valves during the testing process. Having a wrench or pliers on hand can help you make the necessary adjustments to ensure the valves are operating correctly.

4. Common Issues Found During Backflow Preventer Testing

When testing a backflow preventer, several common issues may arise that can prevent the device from functioning as intended. Here are a few of the most frequent problems:

4.1 Leaking Valves

If the check valve or relief valve is leaking, it can prevent the backflow preventer from working properly. A leaking valve can result in water flowing in the wrong direction, which may contaminate your water supply.

4.2 Clogged or Dirty Components

Over time, debris, minerals, or other particles can clog the components of the backflow preventer. This can hinder the device’s ability to stop backflow. Cleaning the components and ensuring they’re free from blockages is essential to maintain functionality.

4.3 Faulty Pressure Relief Valve

If the pressure relief valve is not functioning properly, it can cause a build-up of pressure, which may lead to backflow. Testing the pressure relief valve is an essential step in the overall backflow testing process.

4.4 Improper Installation

Backflow preventers that are incorrectly installed can fail to provide the necessary protection for your water supply. Ensuring that your backflow preventer is installed according to local regulations and manufacturer specifications is critical to its effectiveness.

5. When to Call a Professional for Backflow Testing

While testing a backflow preventer can be done by some homeowners, it is often recommended to call a professional plumber to perform the test, especially if you’re unfamiliar with the process. Certified backflow testers have the expertise and equipment necessary to perform accurate tests and make any needed repairs.

If your backflow preventer fails the test or you encounter issues that are beyond your ability to repair, it’s time to consult a professional. A plumber will have the necessary skills to troubleshoot and fix any issues with the device to ensure that your water supply remains safe.

6. Conclusion: Ensuring Your Backflow Preventer Works Efficiently

Annual testing of backflow preventers is a crucial task to ensure that your water supply remains protected from contamination. By following the proper testing procedures, using the right tools, and addressing any issues promptly, you can keep your backflow preventer functioning properly and prevent costly damage to your plumbing system.

If you're in need of high-quality backflow preventers, testing kits, or professional plumbing services, visit Plumbers Supply Hub for trusted products and expert advice. Taking care of your backflow preventer helps protect your home and water system, ensuring peace of mind for you and your family.

Nielsen Plumbing Inc3.0 (13 reviews)

Nielsen Plumbing Inc3.0 (13 reviews) Best Plumbing4.0 (929 reviews)

Best Plumbing4.0 (929 reviews) Moore's Plumbing Service4.0 (6 reviews)

Moore's Plumbing Service4.0 (6 reviews) D & D Plumbing, Heating and Air Conditioning4.0 (14 reviews)

D & D Plumbing, Heating and Air Conditioning4.0 (14 reviews) Mc Niff Plumbing4.0 (8 reviews)

Mc Niff Plumbing4.0 (8 reviews) TJM Plumbing & Building, LLC5.0 (2 reviews)

TJM Plumbing & Building, LLC5.0 (2 reviews) Why Hard Water Is Harmful to Plumbing Fixtures

Why Hard Water Is Harmful to Plumbing Fixtures How to Replace a Plastic Pipe Fitting That Fails

How to Replace a Plastic Pipe Fitting That Fails How to Repair a Broken Overflow Pipe in Tub

How to Repair a Broken Overflow Pipe in Tub How to Replace a Broken Pipe Bedding Under Floor: A Complete Guide

How to Replace a Broken Pipe Bedding Under Floor: A Complete Guide How to Replace a Galvanized Pipe in Your Home – Step-by-Step Guide

How to Replace a Galvanized Pipe in Your Home – Step-by-Step Guide How to Test an Expansion Tank on Your Water Heater

How to Test an Expansion Tank on Your Water Heater